- February 12, 2024

“Unlocking the Power of Vitrified Grinding Wheels: How this Versatile Tool Enhances Precision and Efficiency”

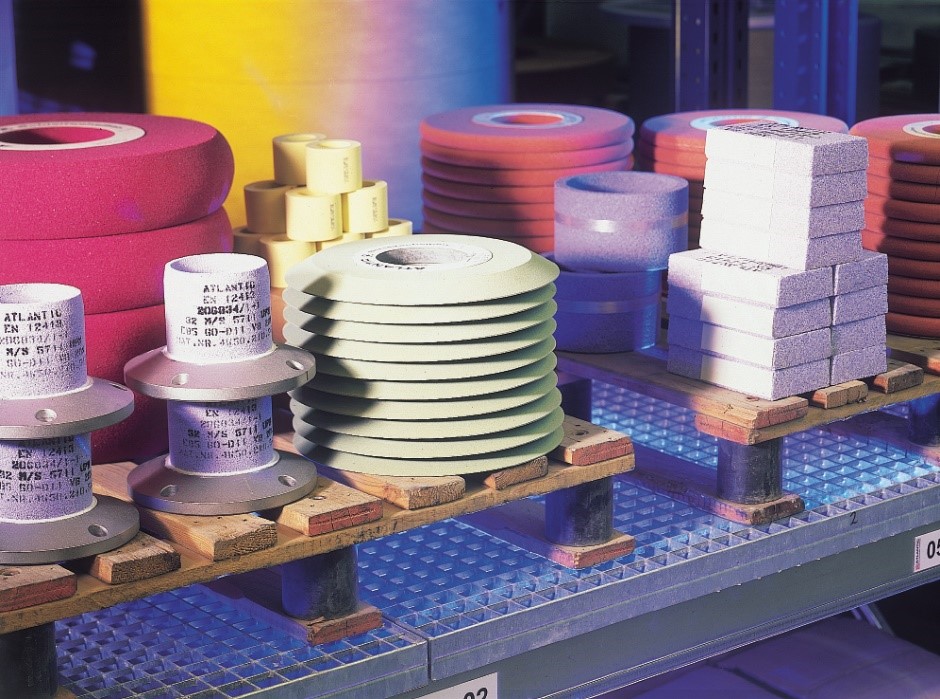

Image Source: Google

When it comes to precision grinding, one tool stands out above the rest – the vitrified grinding wheel. This versatile tool has been used for centuries to shape and refine various materials, and its power and effectiveness are unmatched.

So, what exactly is a vitrified grinding wheel? It is a specialized tool made up of abrasive particles bonded together by a vitrified (glass-like) material. This unique combination allows for exceptional hardness, strength, and longevity, making it ideal for a wide range of grinding applications. Refer: https://www.cdtusa.net/vitrified-bond.

One of the key advantages of vitrified grinding wheels is their ability to maintain their shape and size during use. The vitrified bond holds the abrasive particles in place, preventing them from breaking away or becoming dull. This ensures consistent and precise grinding, even after extended periods of use.

Another important benefit of vitrified grinding wheels is their exceptional heat resistance. The vitrified bond has a high melting point, allowing the wheel to withstand the intense heat generated during grinding without deforming or losing its shape. This heat resistance also reduces the risk of thermal damage to the workpiece, ensuring high-quality results.

Vitrified grinding wheels are commonly used in precision grinding applications, where accuracy and surface finish are critical. Industries such as aerospace, automotive, medical, and tooling rely on these wheels to achieve tight tolerances and superior surface finishes.

One of the key factors that contribute to the precision and efficiency of vitrified grinding wheels is their ability to maintain a sharp cutting edge. The hardness and durability of the vitrified bond allow for continuous and uninterrupted grinding, minimizing the need for frequent wheel dressing or replacement. This saves time and increases productivity, making vitrified grinding wheels a cost-effective choice.

Furthermore, vitrified grinding wheels offer a wide range of abrasive options to suit different grinding requirements. Silicon carbide, aluminum oxide, and cubic boron nitride are some commonly used abrasive materials in vitrified wheels. Each abrasive has its own unique properties, allowing for specific grinding applications such as heavy stock removal, fine surface polishing, or hard material grinding.

When it comes to using vitrified grinding wheels, proper wheel selection and operating parameters are crucial to achieving optimum results. Factors such as wheel hardness, grit size, bond type, feed rate, and coolant selection should be carefully considered to ensure the desired surface finish and dimensional accuracy.

Regular maintenance and dressing of vitrified grinding wheels also play a significant role in maximizing their performance and longevity. Wheel dressing removes the worn-out abrasive particles and exposes fresh cutting edges, ensuring consistent and efficient grinding. It is essential to use the correct dressing tools and techniques to avoid damaging the wheel.

In conclusion, vitrified grinding wheels are a powerful and versatile tool that enhances precision and efficiency in various grinding applications. Their exceptional hardness, heat resistance, and ability to maintain a sharp cutting edge make them invaluable in industries that demand high-quality results. By understanding and unlocking the power of vitrified grinding wheels, manufacturers can achieve superior grinding performance and optimize their production processes.